Learn more about this material in full detail and how it can be used in manufacturing.

Plastic is a common material used here at Xometry. We make thousands of parts out of plastic using CNC machining, laser cutting, 3D printing, injection molding and more. In this article, we will go in-dept into the world of plastic, exploring its composition, characteristics, types, applications, and advantages.

Plastic is a synthetic or semi-synthetic material typically derived from petrochemicals or substances such as cellulose or starch. The basic components are chemically treated to form long chains of molecules called polymers. These polymers can then be molded into various shapes using techniques such as injection molding, extrusion, or blow molding. Some plastics are also known as resins.

Plastic is a material that has become ubiquitous in modern society due to its durability, low cost, and manufacturability. There are many different types of plastics, each with unique properties and characteristics. Some of the most common types include polyethylene, polypropylene, PVC, PET, polystyrene, and nylon. Plastics can be classified into two main groups based on their composition: thermoplastics and thermosets. Thermoplastics can be molded, melted, and remolded again, whereas thermosets cannot be reprocessed when heated.

Plastic was first discovered in 1839 when Charles Goodyear stumbled upon a method called vulcanization, which made rubber more resilient and elastic. Charles Goodyear's invention was also one of the first polymer mixtures to be created. In 1855, Alexander Parkes discovered celluloid, otherwise known as Parkesine. This material is a combination of camphor/lime and cellulose nitrate. It was also the first thermoplastic that became flexible when heated and stiff when cooled. There have been several significant discoveries in the succeeding years, including the isolation of PVC in 1835 by French physicist Victor Regnault; John Wesley Hyatt’s creation of the first synthetic polymer (or industrial plastic) in 1869; and the introduction of transparent food packaging in 1900 by Edward Brandenberger.

Many polymers, both artificial and natural, are used to make plastics. Coal, natural gas, cellulose, starch, crude oil, and salt are a few of the most common constituents in the production of plastic. The polymerization and polycondensation processes, which both require specific catalysts, are the main methods for producing plastics. In a polymerization reaction, monomers such as propylene and ethylene are joined to form long polymer chains. Each polymer has a distinct size, structure, and set of properties that depend on the different basic monomers involved.

Plastics have a few unique properties that make them practical for a wide range of applications. Plastic materials are regarded as:

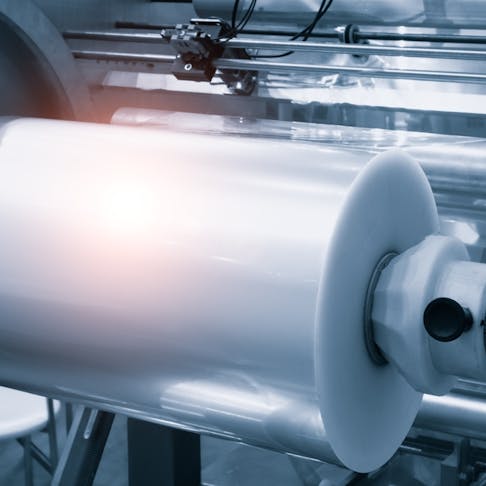

Plastic can come in many different colors and textures, depending on the type of plastic and how it has been treated or processed. Plastic is a synthetic polymer made from various organic materials that can be molded into almost any shape. Some types of plastic are clear and transparent, like those used in disposable water bottles, while others are opaque and available in a range of colors. Plastic can also have different surface textures, ranging from smooth and shiny to rough and matte. Some types of plastic have soft and flexible textures, while others are rigid. Figure 1 below is an example of a plastic custom part made using injection molding by Xometry: